Teaching New Skills at Four Campuses

Scotland’s vision for a highly skilled, enterprising and resilient workforce has required a diversification of courses, teaching methods and spaces within colleges as sustainable technologies develop. West Lothian, Borders, Fife and Edinburgh Colleges wish to construct a modularised and exemplar training facility, termed a Net Zero Accelerator Hub (NZAH), to both teach new students and retrain existing professionals. With no defined site forming part of the brief flexibility has been key to ensure the hub can be adapted to suit any location and customised by each college dependant on their specific requirements.

CLIENT / West Lothian, Borders, Fife and Edinburgh Colleges

BRIEF / Flexibility and Robustness: a demonstrator project for innovative, carbon-locking and sustainable technologies

FLA Team / Ayla Riome, Felix Wilson, Malcolm Fraser

QS / Hardies Property and Construction Consultants

M&E Engineer / Luth's Services

Delivery Consultant / Glulam Solutions

Guiding Principles

While the initial brief requested a modularised facility there can be difficulties around what ‘full modularisation’ can provide, where future adaptation is definedby a specific kit of parts that may limit choices to what a system can accommodate. To avoid this the following Guiding Principles were adopted:

- A Useful, Sturdy, and Adaptable facility, capable of heavy and unpredictable use as both a demonstrator of sustainable technologies and a container for them

- Maximum Sequestration of Carbon: timber core, cladding and insulation, infill and additions

- Minimum use of Toxins: detailed and specified to avoid harmful standard industry solutions, based on a vapour-open and breathable construction

- Circular-Economy Generation: a test-bed for emerging Scottish industries, encouraging mass timber solutions, hemp insulation and cladding and local suppliers – while using EU-wide supply-chains to keep prices competitive.

Simple Outcome

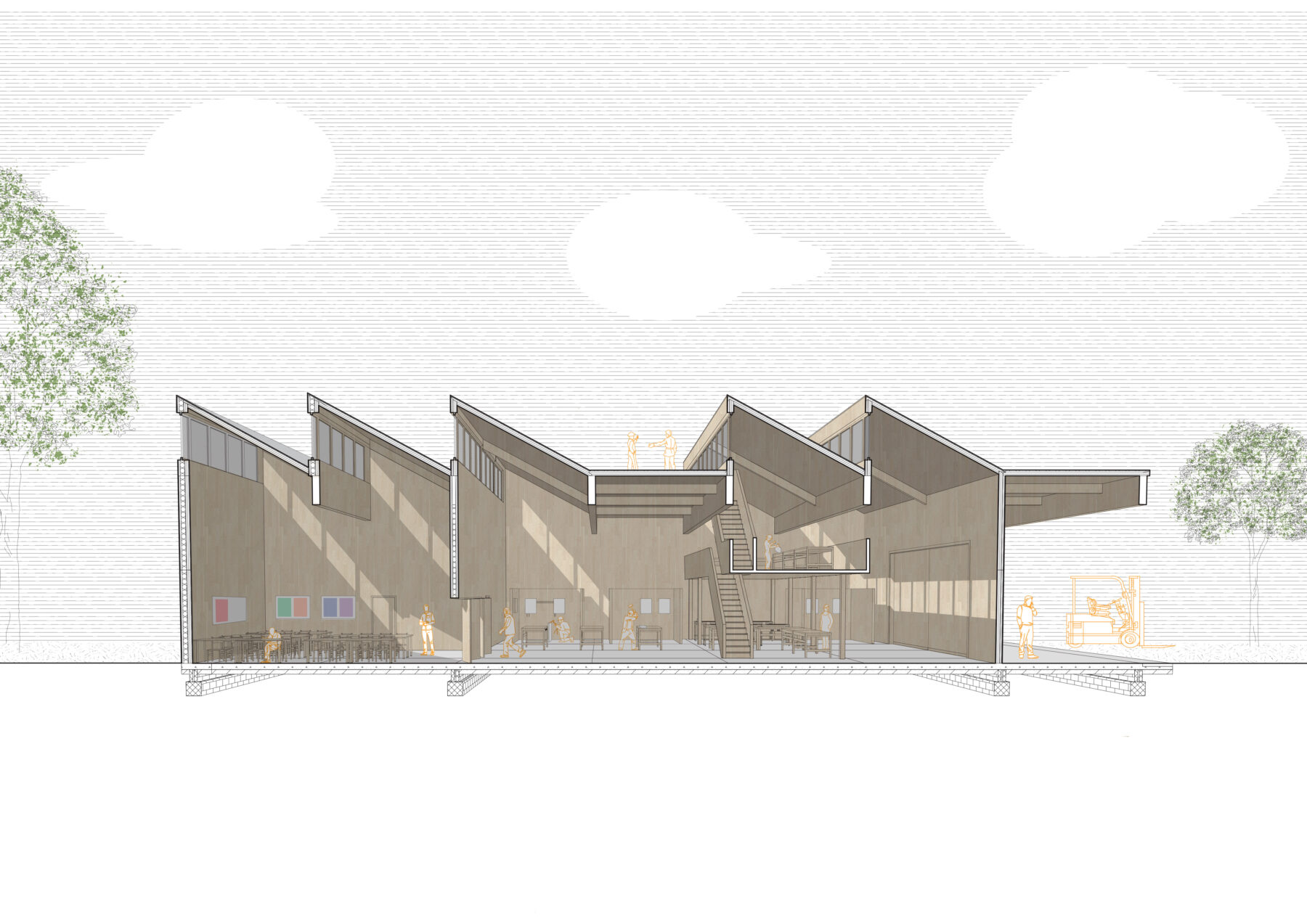

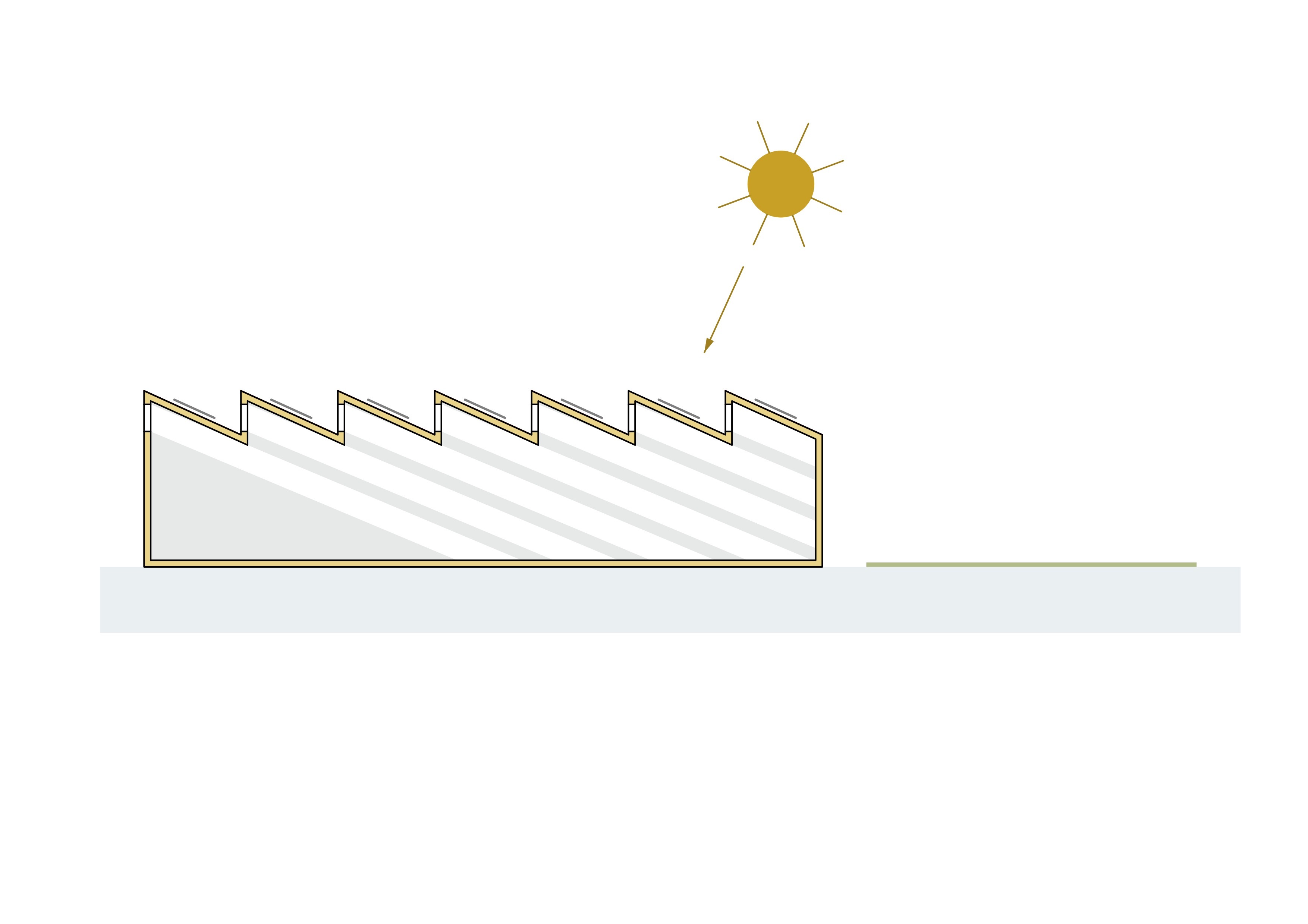

The proposal uses as few materials as possible to limit trades onsite and promote simple construction, increasing the potential for adaptation as well as creating a vapour open healthy and sustainable building. Cross-laminated-timber (CLT) was chosen, maximum carbon-lock and providing the benefits of primary offsite elemental construction while being simple and robust, allowing a variety of onsite variations and configurations and simply-achievable future adaptations. This primary structure will be wrapped in hemp insulation without the need for a vapour control layer and clad also in hemp or Scottish timber. Glulam Solutions, on engineering and delivery, developed a glulam roof structure supporting a sawtooth warehouse type form which, correctly sited, will allow for south-facing sloping roofs with space for solar panels allowing for green energy generation; consistent, diffuse northern light which is good for working; and the opportunity for external ventilation throughout. The space contained sheltered a large, open and flexible space for manoeuvring or dividing to suit.

Methodology

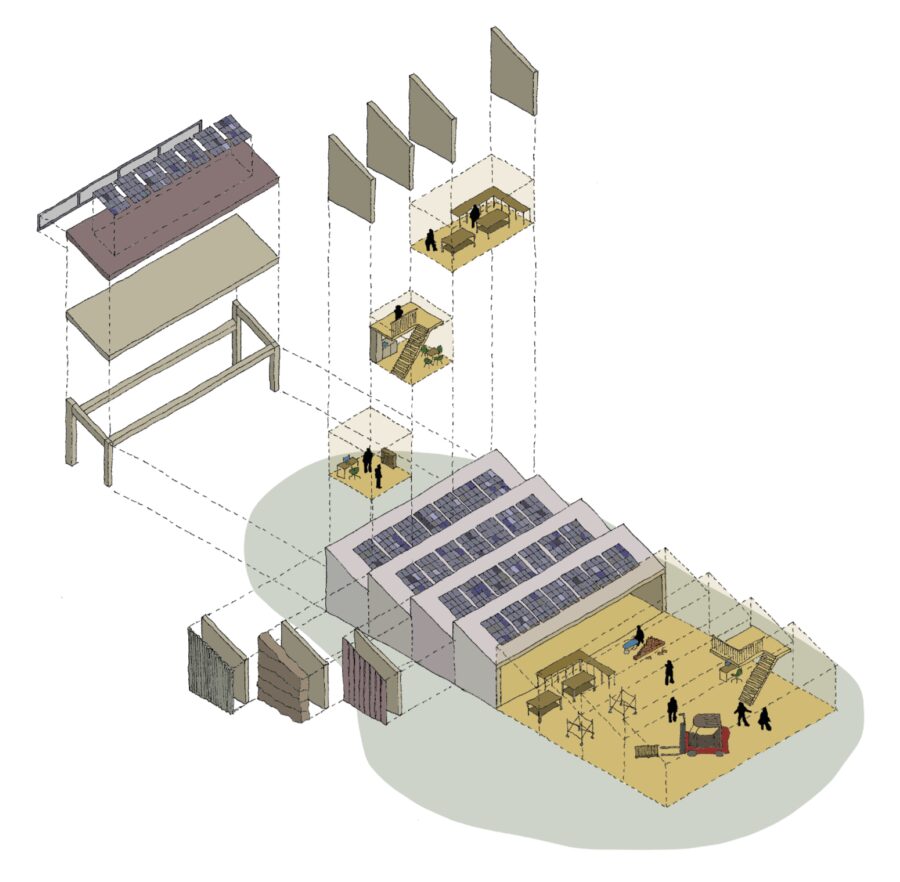

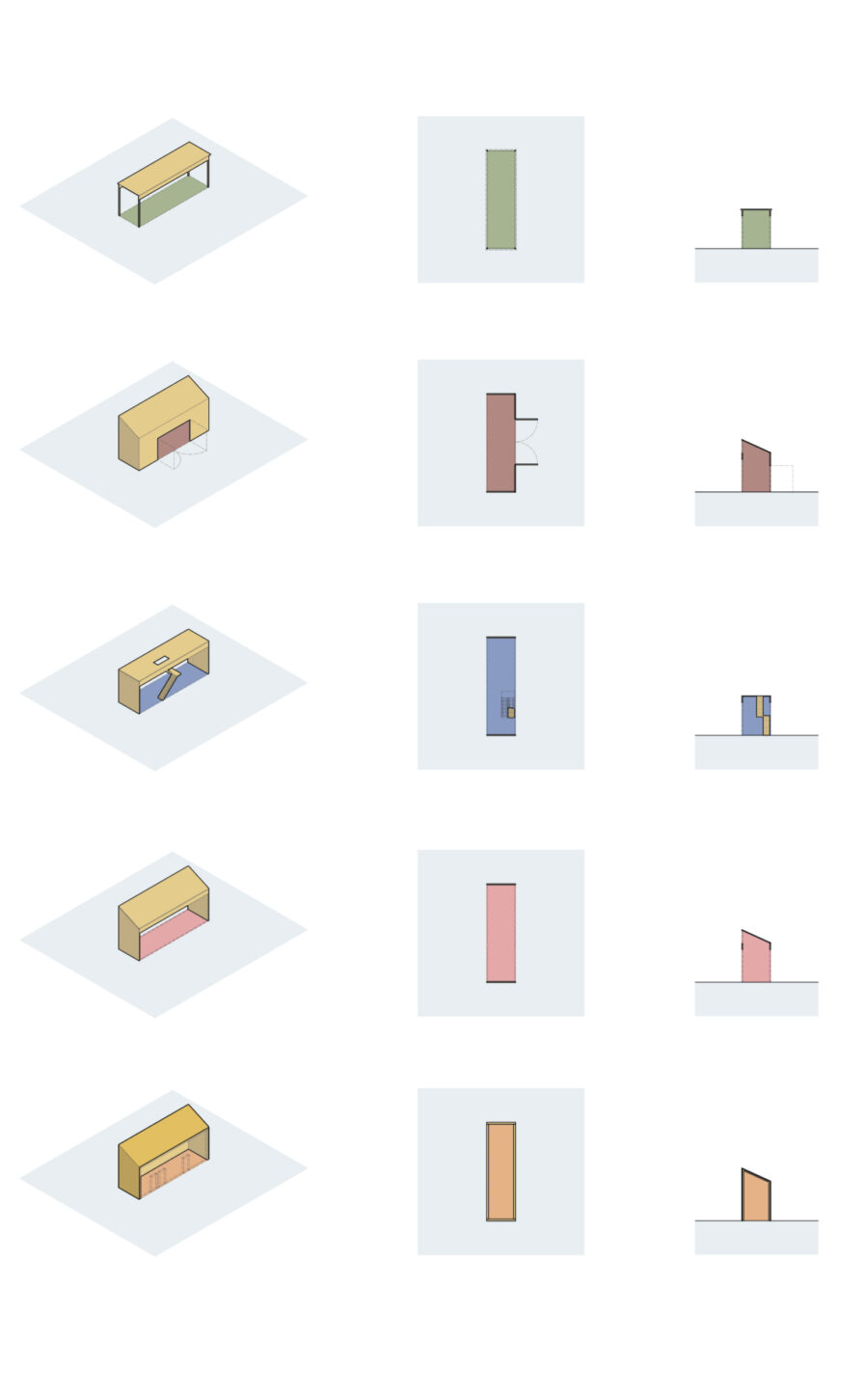

The design methodology for the full NZAH has been split into 3 steps for the colleges to follow:

STEP 1: OVERALL HUB ARRANGEMENT

Once a site is chosen the configuration of the NZAH is considered to mark out any external space required, along with access points and orientation of the building.

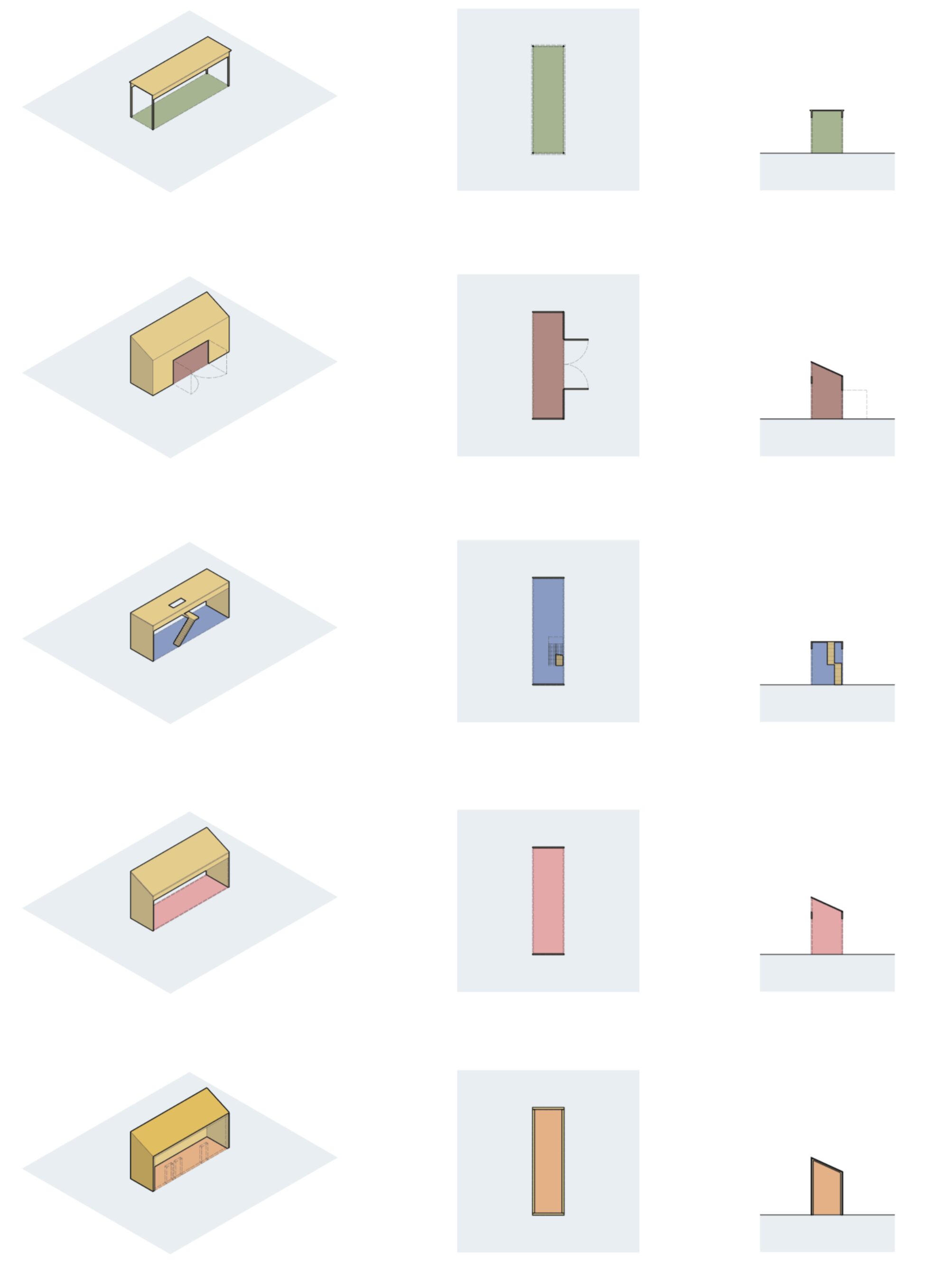

STEP 2: MODULE COMBINATIONS

Each college can choose from a menu of modules to be added together to create the hub. These vary to give as much flexibility as possible and range from an external porch area, to a module designed to passivhaus standards to create a warm teaching environment and give the opportunity for students to learn about the principles involved.

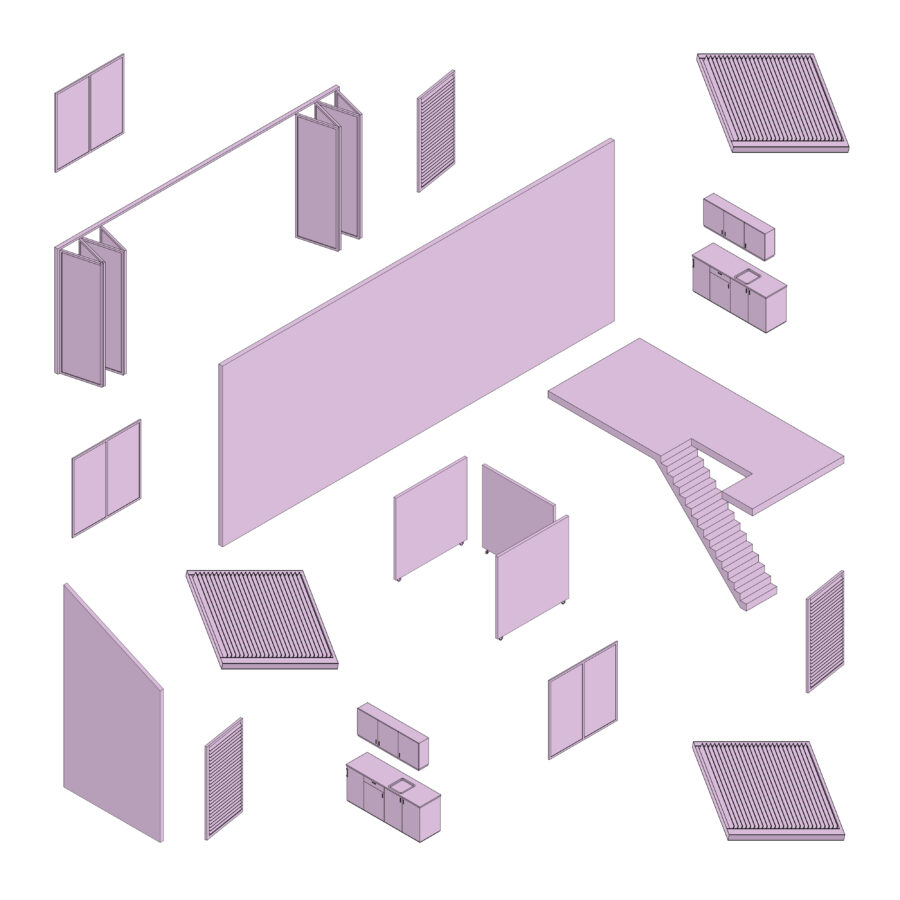

STEP 3: INTERNALS

Different colleges might require different internal configurations and therefore elements such as toilets, kitchens, moveable partitions, mezzanines etc can be located anywhere in the hub.

Luths Services have developed a thermal model and energy generation strategy that uses many of the green skills the NZAH will promote. These services, with their controls and kit, will be exposed internally allowing and encouraging student interaction.

The slow development of CLT production in the UK is noted – though it is also noted that its inherent strength makes it prefect for fast-growing, low-grade Scottish timber. Some elements are designed to be deliverable from the one, limited UK plant – in Scotland. Others are intended to encourage other Scottish mills to step up, with the possibility of wider local, circular sources for future iterations.