We have written about our Studio’s work with natural, carbon-lock, breathing materials. Up until very recently we have also been flummoxed that, in this once inventive and mercantile Scotland, we have been unable to develop these new and urgent technologies with Scottish producers and have been importing, from elsewhere, at financial and carbon expense, products far better made here.

We have been World-Class at talking about this – Papers, Policies, talking-shops and expensively-assembled and sclerotic institutions to tell us how it’s done – and World’s-Last at actually doing it. So, summaries of some virtuous concerns, but also the green shoots that are finally springing-up:

1. The Virtues of Mass-Timber Construction:

CLT (cross-laminated timber – big, thick plywood) and dlt (dowel-laminated timber, mass timber unified by hardwood dowels which absorb moisture differently, locking panels into solid structures) is inherently virtuous:

1. it locks carbon up – of huge significance given our climate-emergency;

2. its massivity means it avoids the toxic rot-dips of timber frame, which is engineered to ultimate flimsiness;

3. it’s breathable, letting CO2, vapour and particulates out, so avoiding the respiratory issues around current, polythene-wrapped construction;

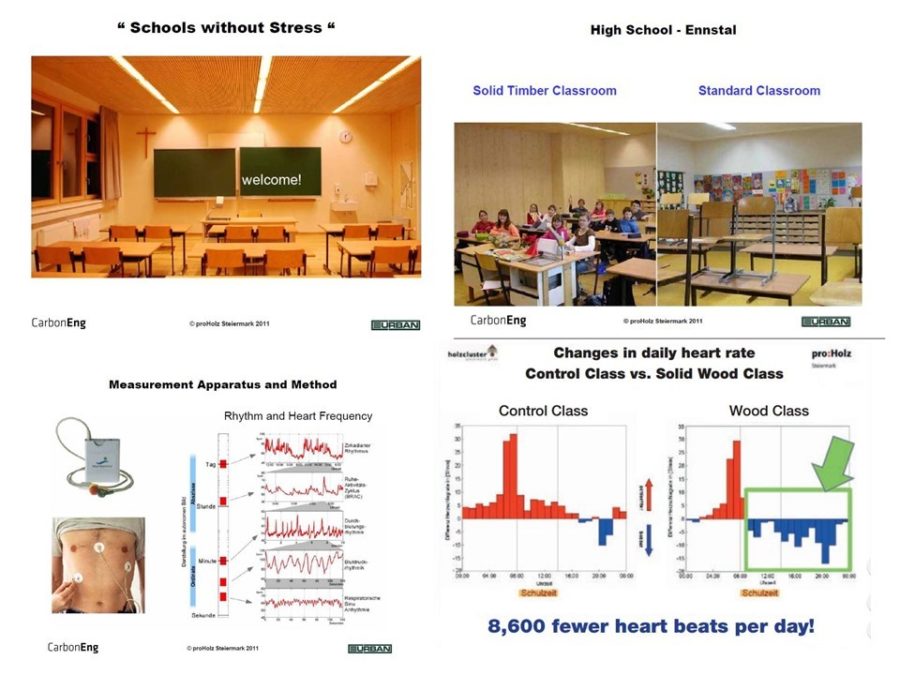

4. when exposed internally it has been proved to engender a calming living and working environment – see “Schools Without Stress”.

In Scotland it has additional virtues:

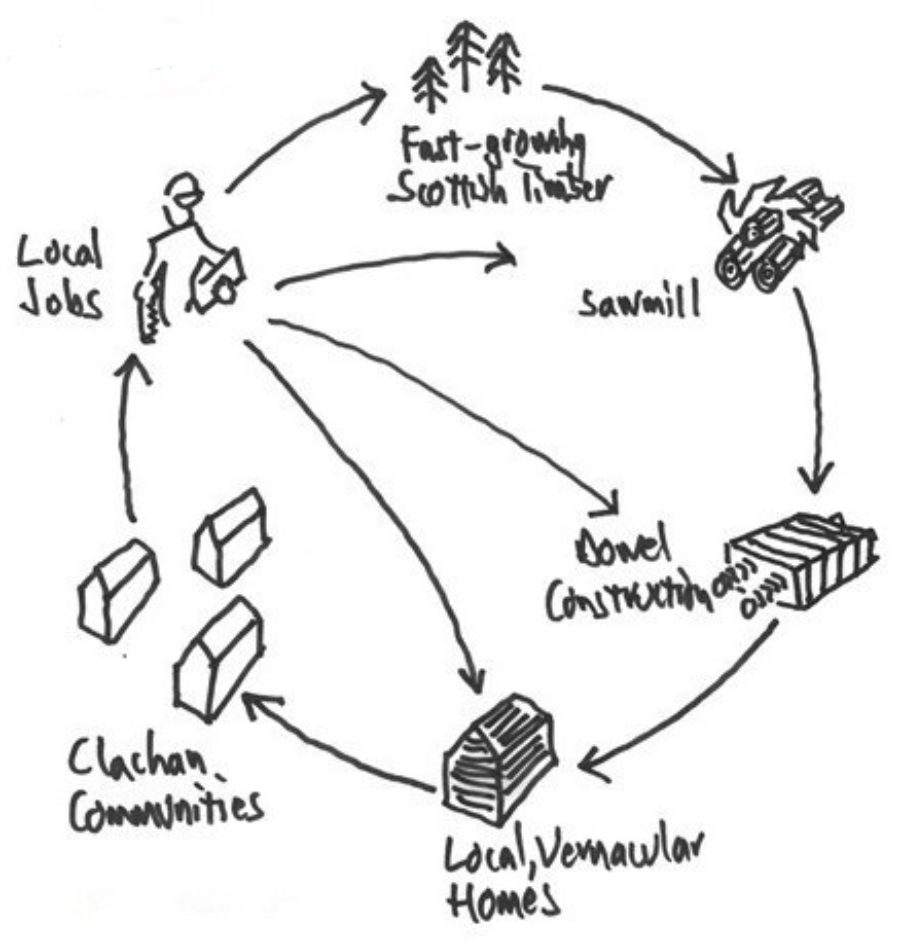

5. it is perfect for Scottish, faster-growing timber as its massivity means it does not require high-grade, slow-growing timber from Russia and the Baltic;

6. local sourced and panelled timber develops the local economy;

7. given the self-harm around Brexit and trade deals it is extra-virtuous to secure local supplies.

The case for the urgent development of these technologies in Scotland is so compelling, it’s interesting to understand the reasons why it is yet to happen – why we source our timber and fund industry abroad and pay for transport from there:

Government has sat back, encouraging academic initiatives but avoiding direct investment in manufacturing – and you can understand their point: there is money to be made in such manufacture, with just a wee bit boldness from a nation with such historic traditions of mercantile innovation;

While Industry has sat back, waiting for Government to put their hands in their pocket – and so much Government money is wasted on subsidising matters of far less virtue and importance you can sort of see their point too.

Green Shoots: pilot Scottish construction timber initiatives we are talking to, and looking to work with:

I sit on the Mass Timber Steering Group of the CSIC Mass Timber Commercialisation initiative, which is working on open-source-shareable digital models with embedded information, with additional partnership with ECOSystems Tech and BSW sawmills, and using the clt bed at the Construction Scotland Innovation Centre;

Kirkcudbrightshire-based Mass Timber Solutions who are advancing their private initiative with James Jones sawmills

2. Hemp, Saviour of the Universe:

Hemp is a wonder-material:

- cheap and simple to grow, it suits the Scottish climate;

- attains surprisingly-high levels of carbon-lock;

- adapts well to building applications: compacts into insulation materials without the need for plasticisers;

- and when bound with lime forms hempcrete – strong, solid, pourable, a virtuous cousin to the badboy concrete.

And where care must be taken: in losing agricultural capacity to its farms.

Green Shoots: friendly initiatives

- We have been assisting Scottish start-up Indinature with setting-up in the Borders. They are now supported by serious innovation funding and in a big factory in Jedburgh, working with the local farmers who will grow for them and ready to manufacture. Exciting!

- We are talking to English-based growers looking for land here, and wanting to innovate with hempcrete and other products – compressed, corrugated cladding possible too!